The automobile industry in China, like most industries during COVID-19, has had taken a great deal of negative impact during the initial phases of the pandemic. Its resiliency and effectiveness in dealing with the outbreak have been tested throughout this ordeal. Nevertheless, China has also taken some steps to alleviate the impact, especially for the electric car industry.

Take a look at our previous article on Electric Car Industry in China Gets Tax Relief and Incentives

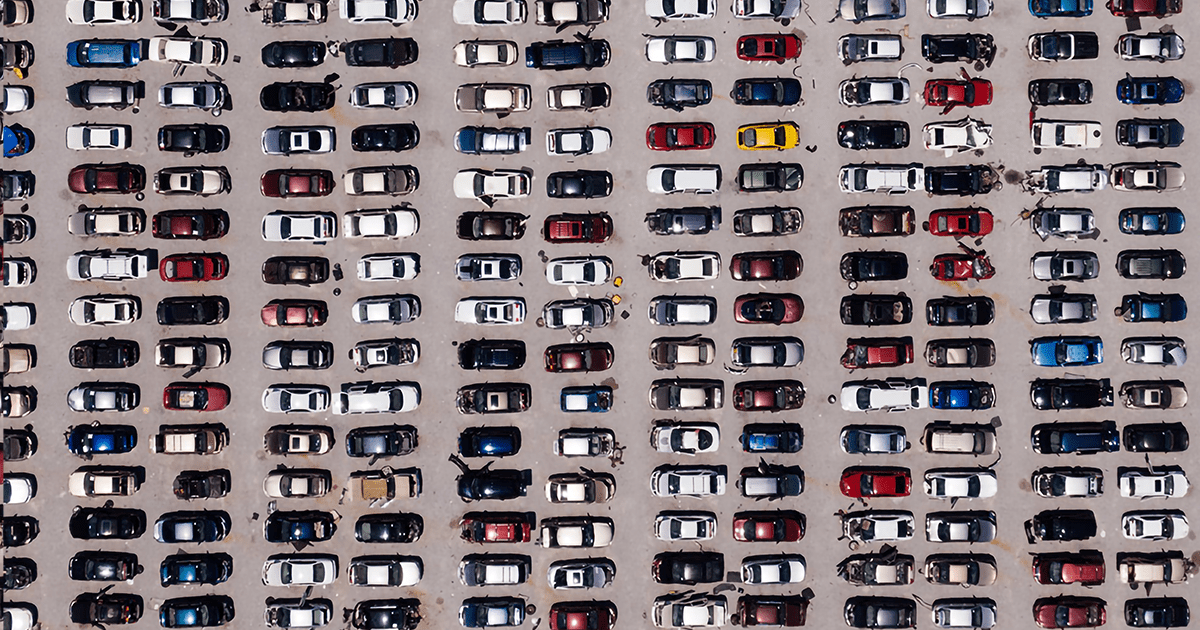

Ever since 2009, the world’s largest automotive manufacturing market has been directed to China. Of the 92 million cars in the world, the country’s automotive manufacturing industry has produced 25.72 million cars from 2009-2019. In 2020, during the brunt of the COVID-19 pandemic, China has inevitably faced a decline in demand for passenger cars. However, its immediate bounce-back from COVID-19 had proven to be reflective of the various Chinese markets, including that of the automobile sales market. Let’s take a look at China’s automobile industry journey through the pandemic, and during the “new normal” after the pandemic.

Impact of COVID-19 on the automobile industry

The debilitating effects of the virus from the vast numbers of individuals infected to the lockdowns and economic turmoil had crippled the automobile industry in China. During the first half of February 2020, the automobile industry worldwide felt a significant drop in car sales by 92 percent, due to factory shutdowns, especially in Wuhan.

As Wuhan is also known as the “motor city” of China, it is no doubt that the city experienced the negative effects of factory shutdowns. Wuhan is famous for automotive brands which established their plant or factory presence in the city. Brands such as Honda, Nissan, General Motors, Renault, and Peugeot Group all have manufacturing plants in the city.

The Next Normal

The post-COVID-19 era or “The Next Normal” is just hopefully around the corner. In most cities in China, local transmissions of COVID-19 have been zero lately. The repercussions of the pandemic may be immense and unprecedented. However, the country has shown economic improvements since the lockdowns. This provides a venue for the automobile industry to gradually return to normal and become resilient ahead. Here are some ways to radically turn the auto industry’s future :

-

Radically focus online or digital channels

The pandemic had opened new doors for the automobile market: online sales, online and offline customer service integration, and e-commerce platforms all can help local and foreign brands reach the Chinese markets more efficiently. Different apps are now offering these services including Tmall, Wechat, Taobao live, among many others.

For social distancing reasons, brands are finding it more effective to turn to live streaming of available products for customers to enjoy. Some brands have even structured online shopping to include contactless test-drives, and car home delivery services.

-

Shift to recurring revenue streams

The pandemic brought about uncertainties that have rendered consumers to be more conscious of their current spending habits. Large up-front purchases and bulk purchases of non-essentials are not as easy to make as before. However, consumers may still have a preference as much as it was before the pandemic for short-term, subscription-based offers that are relatively low priced.

Among these choices could include short-term leases as an option for consumers instead of traditional car sales. Flexibility, consistency, and mobility especially in the automobile industry are important these days. Consistency in the revenue stream could also come in the form of “subscriptions” such as software upgrades and over-the-air updates for vehicles.

-

Optimize asset deployment through strategic partnerships

Original Equipment Manufacturers (OEMs) of automotive products and their suppliers all face the same travesties presented by the pandemic. This is because consumers tend to spend mostly on essential products such as basic food, clothing, insurance, and mortgage or rent. As a result, technological investments may not be in high priority.

To maximize profitability, partnerships and collaborations among supporting and competing companies may become more of a solution than a problem now and in the future.

-

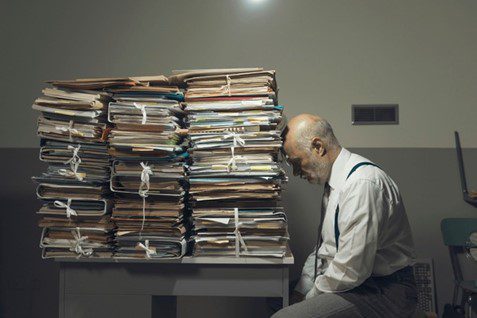

Embrace zero-based income statements

Zero-based income statements are projected zero-based budgets. They are called zero-based because all expenses to be budgeted necessitate justification for every new period that is to come. Therefore, it reconstructs their income statements from scratch.

There are zero bases from previous performance and every department, function, or area within an organization must be analyzed for their respective costs and needs. When companies identify the bare minimum necessities required for each functional area’s survival, they do not need for comparison against the previous year’s financial performance. This is especially the case since the impact of COVID-19 is unprecedented. Therefore, the process allows top-level goals to be implemented by specifically focusing on the functional areas they belong to. This will then be measured against previous results and current expectations for that area.

-

Build resilience into the supply chain

There were much urgency and effort put into building supply chains in the industry that could withstand the challenges presented by the pandemic. The fragility of the global supply chains during the pandemic showed a certain lack of resilience of the global system as a whole.

Companies in the automobile industry must explore local sourcing and in-sourcing of the manufacturing process or its parts. Relying on a single country for the bulk of manufacturing needs showed a weakness in strategy, as shown during the early weeks of the pandemic: everyone suffered.

Conclusion

All these improvements in the automobile industry are only possible with effective leadership and flexibility of the work environment. The markets these days could easily shift. Schools conducted online classes, restaurants and supermarkets upgraded to online takeouts, even a few doctors in some parts of the world did medical consultations online; the world has changed fast because of the pandemic.

Since the improvement of the situation in China, a lot of those changes have stayed and are becoming permanent improvements to the business processes involved. China’s automobile industry is well on its way to full recovery. However, because the changes brought about by the pandemic are for the better of the markets and the industry itself, the transition to keep up with the world leaders and competition in the industry is bound to be rigorous.

Contact us

S.J. Grand’s business strategy optimization services will keep your business ahead of the future and compete with industry competition. Contact us for consultation and assistance.

Moreover, we have been at the forefront of promoting full automation of business operations, especially for startups and SMEs. We have introduced our Cloud-based advanced solution, Kwikdroid, to make business transactions easier with us, no matter what type or size of the company. Visit our Kwikdroid page to learn more about the services we offer.

You may be interested to read about how to manage your company remotely using the advantages of Kwikdroid. Check it out!